Packaging, Pulp and Paper

The pulp and paper are one of the largest and complex industries in the world with many different kinds of products and processes that manufacture pulp and paper from wood or recycled fiber. Demanding applications and difficult processing conditions in pulp mills create challenges for accurate, repeatable, and reliable measurements. This industry places high demands on efficient use of raw materials and energy, productivity and plant availability to produce high-quality products and solutions and is highly competitive and must meet ever-changing market needs. Using state-of-the-art technologies in the pulp and paper industry leads to higher production efficiency and significantly reduced material cost and energy consumption throughout the manufacturing process.

All Applications

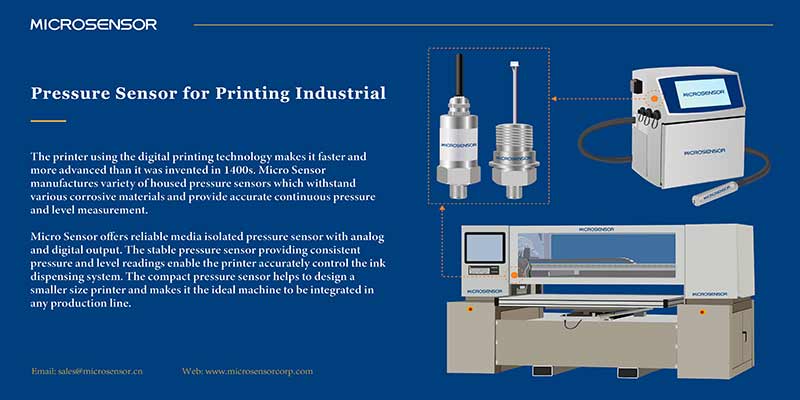

Pressure Sensors in Printing Industry

Due to the use of digital printing technology in today's printers, printing has become more advanced and rapid than it was invented in the 1400s. Micro Sensor produces...

Filling, Sealing and Cutting of Chip Bags

Engineers who want to make the process of sealing and cutting as accurate as possible, can use Color mark sensors. These sensors help them to...

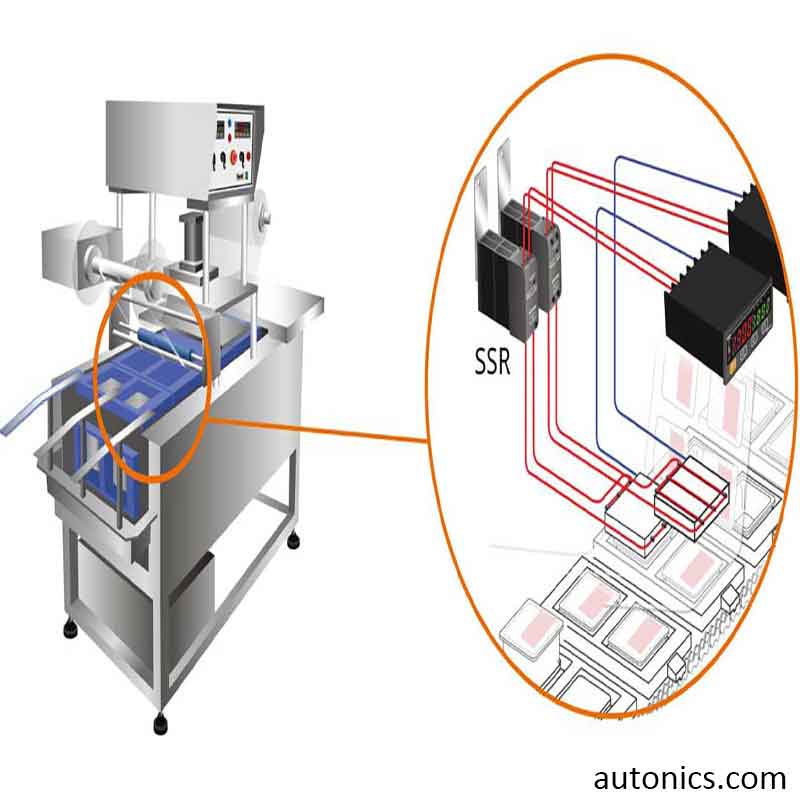

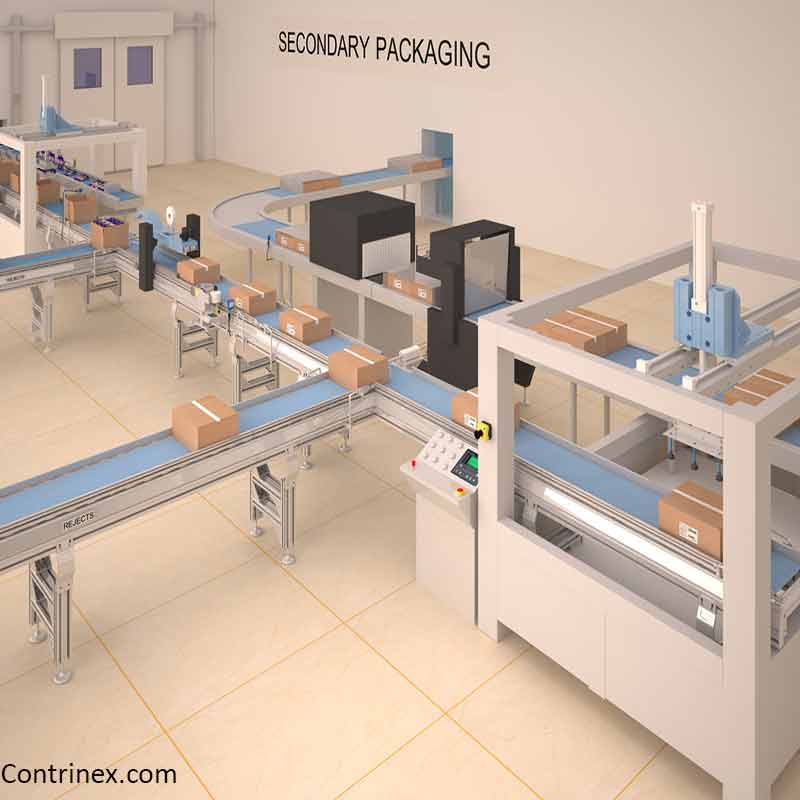

Selected Applications From Packaging Industry

Solid state relays can be applied with temperature controllers in cup sealing/packaging machines...

Transparent-Object Sensors with Patented UV Technology for Reliable Detecting and Precise Counting of Clear Plastic Trays

During automatic packaging of fast-moving merchandise in managed conditions, thermoforming lines manufacture transparent plastic...

Using Photoelectric Sensors to Control the Process of Bulk Food Packing

During the process of managing high-volume, automated food-packaging, engineers need sensors to preserve an optimum amount of control across on...

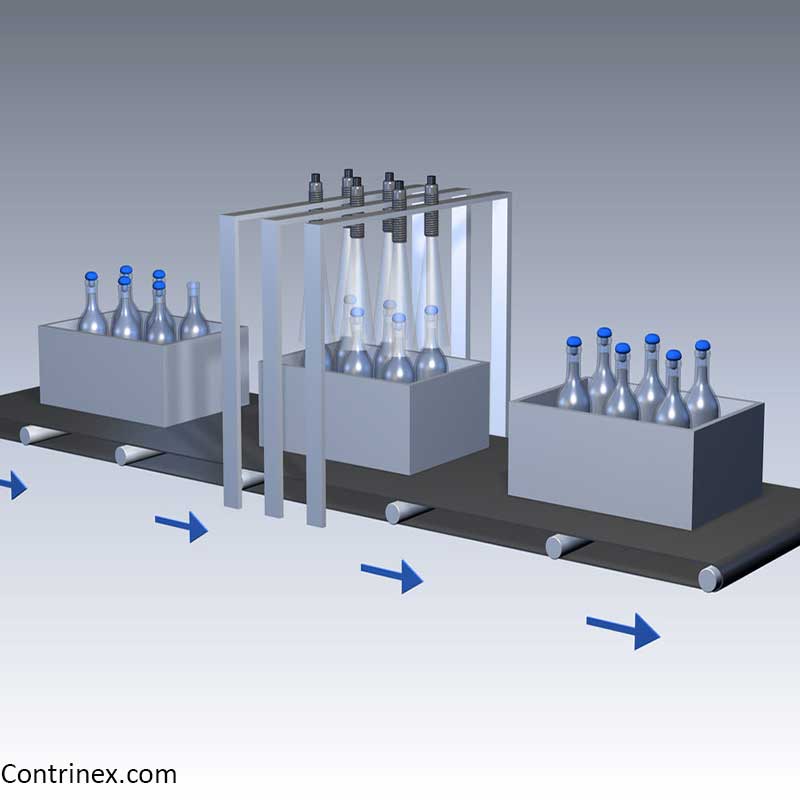

Detecting Bottle Caps through Cardboard Case on High-Velocity Packaging Lines

In beverage manufacturing, a final, pre-shipment check is done on all bottles after the corrugated cardboard case has been sealed. Bottles can...

Reliable Tool Changing in Packaging Machines by RFID

Read/write modules established on the packaging machines read the data in tools' tags. If RFID data shows that a part of a device is missing, or...

Figuring out Clear Plastic Sheets during Thermoforming through Transparent-Object Sensors with Patented UV Technology

During automated packaging, high- velocity thermoforming lines manufacture transparent plastic blister-trays from continuous...

Minimizing the Number of Double-Bottoms during Aerosol Can Manufacturing via Detecting Their Mass

A manufacturer of aerosol cans desires to make certain that, for every can, just one bottom is inserted into the press that applies and crimps the...

Figuring out Translucent Targets during Blister Packaging via Fiber-Optic Sensing with Blue Light Source

A packaging enterprise supplies toothbrushes in single blister packs. Production quality checks consist of last verification that the product is found in...