Detecting Clear Packaging Trays on Automated Packaging Lines through Transparent-Object Sensors with Patented UV Technology

Throughout automated packaging of medical products under sterile conditions, clear plastic tray bases are conveyed to filling stations. Sensors are required to figure out the trays as they arrive, allowing the load cycle to continue without the danger of a line stopping.

Standard photoelectric sensor, using red light sources that can visible, have proven to be less reliable because they cannot reliably distinguish between “plane” and “non-plane” conditions.

Standard photoelectric sensors, using red-light sources, have proven to be inappropriate since they can't differentiate dependably between ‘tray present’ and ‘tray not present’ conditions.

Transparent-object sensors with UV LED-light sources are designed for this application. They work with ultraviolet light polarized at 275 nm and their installation is easy.

An industry-standard normally open PNP output provides ultimate flexibility. Furthermore, IO-Link is enabled on PNP versions at no extra cost.

Another output sends a stability alarm if the sensitivity decreases, showing the need for preventative maintenance.

The sensor's vigorous construction with an M8 connector, warrants reliable working. Their detection range is up to 1200 mm. Sensitivity parameters are saved on the sensor’s onboard memory and can be retrieved or updated remotely through IO-Link. It's notable that the solution is highly affordable.

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

Identification of Switch Washers with Inductive Sensors during Their Production

Go to application

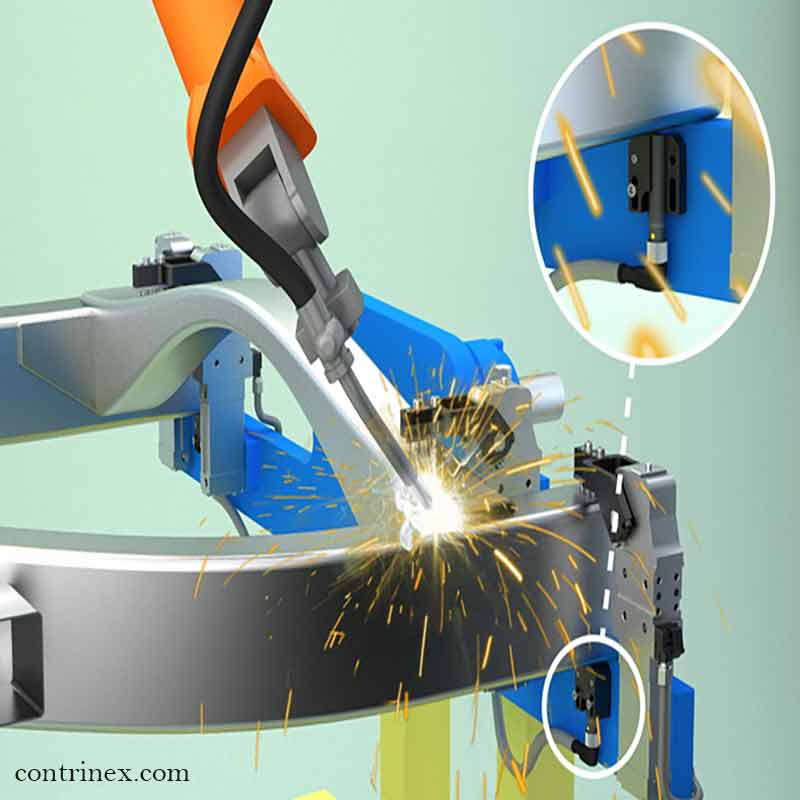

Checking Complete Closure of Tools with Inductive Proximity Sensors

Checking the Engine Part Position during Manufacturing with Inductive Sensors

Related Products