Proximity Sensor Types [Features, Advantages and Selection tips]

How does a proximity sensor work?

Proximity sensors that also called detectors are non-contacting technology to detect or sense the presence or absence of nearby objects which come within range of their oscillating field. When the sensor detects an object- either a person or a piece of equipment- in its determined range the associated method of detection will record the activity and transmit the data back to the cloud through Cloud Connectors, warning devices, or platforms. The proximity sensor types detect objects in milliseconds and and their range of detection vary from 1 mm to 300 m..

They are widely used in a wide range of environments and many applications in industrial and manufacturing such as conveyor systems, touch screens, parking sensors, warning systems, mobile devices and industrial Automation.

Proximity sensors are also used in inspection tools that enable companies throughout the world to gain real-time data visibility that drives productivity, safety and inventory management. To know more, you can check proximity sensor working principles page.

Types of the proximity sensor

Proximity sensors are available in a variety of models based on their specifications and the applications they are used in.

Some of them are used to detect materials, but some are useful to detect different environmental conditions.

Different types use varying sensing technologies but they all have the same purpose. According to methods used to detect the object, there are five widely-used types of proximity sensors, including:

- Inductive Proximity Sensor

- Photoelectric Sensor

- Capacitive Proximity Sensor

- Magnetic Proximity Sensor

- Ultrasonic proximity Sensor

Inductive Proximity Sensor

Inductive proximity sensors can detect metal objects without contact and at distances of up to 60 mm. standard inductive sensors can operate over significantly greater distances.

They are used solely for the detection of metal objects. When a metal object comes closer within the magnetic field generated by the sensor, the resulting currents are induced from an additional load and the oscillation ceases.

This causes the output driver to operate and, depending on the sensor type, a NO, NC, or NO + NC output signal is produced (common example: proximity sensor pnp nc). The distance this sensor operates depends on the actuator's shape and size and is strictly linked to the nature of the material.

The Composition of an inductive proximity sensor includes four elements – the coil, the oscillator, the trigger circuit, and an output.

Inductive Sensors housing come in 2 types: shielded proximity sensor or Unshielded Versions: to be mounted Flush(Embedded) or Non-Flush(Non-Embedded) in metal while newer Quasi-Flush(Semi-Flush) models are Shielded but their sensing distances are best when mounted Non-Flush.

Advantages of inductive detection

There is no need for physical contact to detect the object, thus avoiding wear and enabling fragile or freshly painted objects to be detected.

- High operating rates.

- Offer a fast response rate.

- They are resistant to industrial environments, explosive atmospheres, or in harsh environments

- Their technology is Solid and because there are no moving parts, therefore has a long service life and extreme ruggedness.

- Inductive sensors are independent of the number of operating cycles.

- These types of sensors offer the ultimate in precision and reliability.

- In the sense of price, they are considerably cheap.

Capacitive proximity sensors

Capacitive switches are non-contacting technology that senses metal as well as nonmetallic materials such as paper, glass, liquids, cloth liquid, powders, and granular.

This device can detect lightweight or small objects that cannot be detected by mechanical limit switches. They are similar to inductive sensors but there are differences.

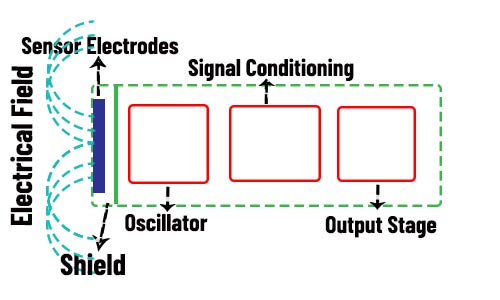

Capacitive proximity sensors produce an electrostatic field instead of an electromagnetic field. When an object comes into the sensing surface of the capacitive sensor, it enters the electrostatic field of the electrodes and changes the capacitance in an oscillator circuit.

So, the oscillator begins oscillating. The trigger circuit reads the oscillator’s amplitude and when it reaches a specific level the output state of the sensor changes. As the target moves away from the sensor the oscillator’s amplitude decreases, switching the sensor output back to its original state.

This sensor consists of five components named:

- Sensor Housing

- Sensing Face

- Mounting Nuts

- Sensor End bell

- Connection Interface

Proximity capacitive sensing technology can be used in various aspects of life:

- These sensors are extremely used in touch switches, consumer electronics, and IoT products.

- In the solar and electronics and packaging industry

- In wood processing machines

- In the plastics industry to Detect rubber and plastic granulates

- In the pharmaceuticals and chemicals industry to detect various liquids

- Identification of Paper and Plastic from Recycling Materials

Advantages of Capacitive proximity sensors

- Non-Contact identification of both metallic and non-metallic objects

- Used in harsh industrial environments, which reduces machine maintenance costs and downtimes

- Strong anti-interference

- Highly wide range of applications

- Minimal sensitivity to dust and moisture that cause reliable detection of material

- Provide rapid response by high switching rate

- Detection of liquid material through non-metallic barriers like glass and plastic

- No moving parts so there is long operating life

Magnetic Proximity Sensor

Magnetic proximity sensors are non-contact object detection that detects the presence of magnetic objects like permanent magnets.

Unlike their small package, they operate in very long sensing ranges and can detect magnets through walls of non-ferrous metal, stainless steel, aluminum, plastic, or wood.

"The target, characterized by its magnetic field, triggers the switching process when it enters the detection range of the sensor and alerts a microprocessor or some other computational unit. The switch may be a reed switch or the device could operate due to inductive, variable reluctance, magneto resistive, or Hall Effect operating principles."

These non-contact sensors are used in many industrial applications

- Detection of the open or closed status of windows, doors, gates, trunks, containers,

- Machine tool position sensing,

- Limit switches for actuators in industrial automation

- Valve position sensing

- Food processing machinery, revolution sensing,

- Elevator position sensing

Advantages of magnetic Proximity sensors

- Non-contact operation

- Long sensing ranges up to 70 mm unlike its reduced size

- Detection of permanent magnets through various materials like wood, plastic, non-magnetic metals

- No moving parts so long service times

- Robust and Maintenance free

- Operate in the high-temperature range

- Used in harsh environments and they don’t affect by dust, heat, or vibrations

Ultrasonic proximity Sensor

Ultrasonic proximity sensors without making physical contact detect the presence of an object. This sensor is an electronic device that will measure the distance of a target by transmitting ultrasonic sound waves, and then will convert the reflected sound into an electrical signal.

It can operate in a broad range from a few centimeters up to several meters. The transmitter and the receiver are the two main parts of this sensor. Ultrasonic solutions are often used where the target material is solid or liquid and larger sensors or longer sensing distances are required.

This type of sensor is designed for very specific applications as follow:

- Used as level sensors to detect liquid levels in closed containers and tanks

- And stream or river level monitoring

- Trash Level Monitoring

- Uses in Production Lines

- Produce images of internal organs, identify tumors, and ensure the health of babies in the womb in the medical industry

- Robotic

- To detect people in the counting system

Advantages of Ultrasonic proximity Sensor

- Used to detect all types of parts regardless of shape, transparency, or color.

- Prepare in small size and low cost

- High operating frequency and high sensitivity

- Factory noise air pressure, humidity, smoke, dust, vapors do not affect ultrasonic sensor operation

- Ultrasonic sensors can work with round, moving targets, such as film, paper, rubber, or steel.

- Operate in a wide range of several meters

- Used in dark, harsh environments and any adverse conditions.

Photoelectric Sensor

The photoelectric sensor can be used to detect the distance and presence of an object by using light at a distance of up to 200 meters. There is a light source and a sensor that detects the light. Light rays are converted into electrical signals. Through-Beam Sensors Retro-Reflective Sensors Diffuse Reflection Sensors are Different types of photoelectric sensors.

Photoelectric sensors application

- Computers and smartphones,

- Copy machines and light fixtures that turn on automatically in the dark.

- Alarm systems, and systems that can detect the presence of objects.

- Biomedical devices for breath analysis and heart rate monitoring in healthcare

Advantages of Photoelectric Sensor

- Operate in a wide range

- Detection of small objects at a large distance

- Detection of all kinds of materials

- Long life and Quick response

- Not affected by electromagnetic interference

- Reliability and High sensitivity

Which proximity sensor is the best?

When choosing a proximity sensor, you must determine the type of object to be detected, is it solid, liquid, granular, metallic?

Also, the distance between the sensor and the object must be considered. the shape of the object detected is important in choosing the right proximity sensor.

What are the applications of proximity sensor?

- In automated industries like Packaging Printing and Process industry, military, robotics, rail, aerospace, etc.

- Detecting motion position & controlling the motion of an object

- Used in the production of transformer & coil

- In traffic sensors for noticing the moving car

- Measure the distance & position of the tool

Please have a look at our other Proximity Sensor articles:

- Inductive Proximity Sensor Types [Working Principle, All Types Explained, Terminology, Outputs]

- Everything About Top 5 Proximity sensor Manufacturers in UAE

- Most popular brands for proximity sensors in 2022

Recent Posts

-

From Lab to Launchpad: Pressure Sensor Industry Certifications

In the intricate world of technology and precision engineering, where every measurement matters a …16th Mar 2024 -

Stand Out, Stand Certified: The Art of Pressure Sensor Safety

Stand Out, Stand Certified: The Art of Pressure Sensor Safety Welcome to the world of performance …9th Mar 2024 -

Robotics in Food and beverage Industry

Our lives depend on the food and beverage industry and it is in a constant state of evolution, …5th Mar 2024

![Proximity Sensor Types [Features, Advantages and Selection tips] Proximity Sensor Types [Features, Advantages and Selection tips]](https://cdn11.bigcommerce.com/s-sgprcd6/images/stencil/1193x795/uploaded_images/proximity-sensor-types.jpg?t=1644062126)