Precise Detection of High-Speed Spindles' Position Using Miniature Inductive Sensors

High-speed machining centers are equipped with automatic tool changers. However, these centers demand exact measurements of the spindle's position. A miniature sensor should be present to detect the position of a slotted centering disc mounted on the drive motor shaft. The demanded angular resolution translates to a better than 0.01mm positioning accuracy.

What can be the best choice?

We introduce inductive sensors as the best solution for this challenge.

The features of these sensors:

• Built-in M5-diameter sensors

• Length: 25mm

• The sensor's material: V2A/AISI 303 stainless steel

• Minimal risk of incidental collision with the disc • due to a 0.8mm detection distance

• Excellent resistance to vibration and shock due • to Vacuum-encapsulated electronics

• No need for extra mechanical or electrical • protection

• The least maintenance demands are due to Fit-and-forget operation

• Accuracy: better than the demanded amount of 0.01mm

Where are these sensors mounted?

They are mounted straight into the wall of the housing.

How do they work?

The centering disc is boarded in a rotary-encoder housing mounted on the drive motor shaft.

Inductive sensors detect the centering disc's position repeatedly and reliably.

They have hermetically sealed cable entries and PPE sensing faces, making them take up minimal space.

Connection to the customer's control system:

These sensors are configured with an industry-standard PNP normally-open interface. Such an interface is connected to the customer's control system through a flexible, oil-resistant PUR sheathed cable.

Among the leading manufacturers of automotive sensors, Contrinex is one of the largest. Step in to get to know Contrinex company.

Check out our article for more information on photoelectric sensors:Inductive Proximity Sensor Types

Do You Need Help For Field Installation?

We have thought everything through, submit your request for an on-site support.

Do You Need More Solutions? Have a Look at Our Vast Applications

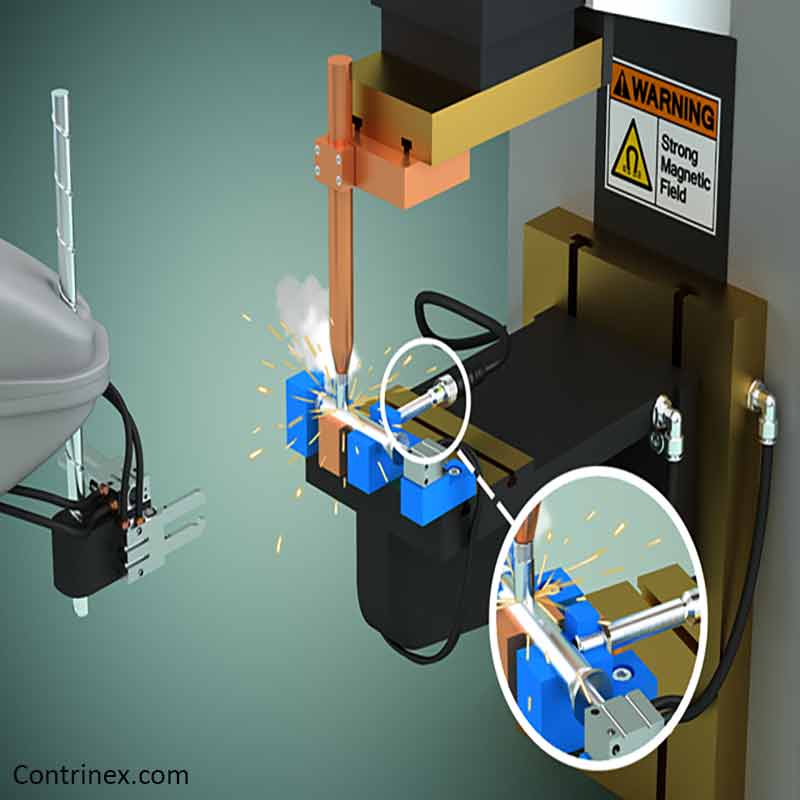

Providing Significant Preservation with Minimum Cost in MF Resistance Welding of Aluminum Assemblies by Factor 1 Weld-Immune Sensors

Checking the Speed for Mobile Compost Turning Equipment

Selected Applications From Semiconductor/Display Industry

Related Products